Product

Features

Is it imported: No

Installation method: Matching

Brand: Xiyangyang

Function type: Rolling door machine power storage box

Shell protection level: IP44

Cover material: circuit board + battery + shell

Order number: 0021

Processing customization: No

Rated current: 30 (A)

Product certification: CCC

Series: AC/DC power storage box

Shell material: steel plate

Material number: 66

Specification: 220V to 24V

Is it a dedicated source for cross-border export: No

Item number: 166

Product Details

XYY Xiyangyang series electric rolling door machine has multiple operation functions such as remote control, electric, manual, etc.; it is suitable for fire protection matching requirements and has self-locking and anti-theft functions;

It has beautiful appearance, safety and reliability, long service life, easy installation and maintenance, small size, light weight, strong horsepower and other advantages.

It is widely used in exhibition halls, hotels, shopping malls, store auxiliary, factory buildings, garages, warehouses, and is an ideal supporting product for ordinary rolling doors and fireproof rolling doors.

Shell: Aluminum alloy shell, solid and light.

Gear: Made of high-quality alloy steel, specially treated to ensure the strength of the winch.

Brake structure: Special device mechanical brake, can brake at the moment of power cut off, ensuring absolute safety of braking.

Limit system: accurate stroke control, easy adjustment and large controlled stroke.

Transmission system: high precision, smooth operation, low noise. Anti-fall device: prevent accidental injuries and ensure safety.

1. Working environment and working conditions of rolling door machine:

● Ambient air temperature changes with the season

Ambient temperature: -25oC — 55oC

Relative humidity is 90% (25oC)

● Short-time working system, continuous operation time

Single-phase motor shall not exceed 7 minutes, three-phase motor shall not exceed 10 minutes

2. Functional characteristics of rolling door machine:

● The rolling door machine has two voltage drive models of AC 220V and 380V, equipped with manual buttons and anti-theft lock boxes, and is equipped with remote controls, with long remote control distance and convenient operation;

● The upper and lower travels of the rolling door are automatically controlled by the limit switch, with accurate and reliable positioning and safe opening and closing;

● In the event of a power outage, manual operation can be performed through a quick release device or a hand-pull chain, which is convenient and labor-saving;

● The whole machine runs smoothly, with low noise and small vibration.

● An overheat protection device is installed inside the motor. If the motor is frequently opened and closed, when the temperature reaches 110℃, the power supply can be automatically cut off to protect the motor from burning. When the temperature drops to 70℃, the device can be started again.

3. For main specifications and technical parameters, please call us or refer to the catalog for details.

4. Safety precautions:

● The rolling door machine should be installed and maintained by professionals and must have good protective grounding, otherwise it may cause personal safety;

● When the rolling door machine is running, it is strictly forbidden to stand or pass under the door, and there must be no obstacles under the door curtain;

● Regularly check the moving parts of the door body to ensure that the operation will not be obstructed, keep lubricated, and the operating sound is normal, otherwise it may cause personal safety and affect the service life.

5. Installation and debugging:

● This product is manufactured according to the right installation plan (looking from the room to the outside of the door). If it needs to be installed on the left, the 4 screws M5 on the brake housing should be loosened, and then the housing should be rotated 180° and re-balanced and locked, and the white and green lines on the button switch should be connected in reverse;

● The rolling door machine should be installed horizontally, the reel should be horizontal and concentric, and the door curtain should be raised and lowered without stagnation;

● Drive chain adjustment: first loosen the fixing bolts M6 of the small sprocket on the bracket plate, and then adjust the 2 bolts M8 on the gearbox of the rolling door machine to make the droop of the drive chain 3-6mm (adjust before installing the door curtain), and then tighten the 3 support nuts M10;

● Adjustment of the up and down travel of the door curtain: Before testing the machine, loosen the two set screws on the limit slider, raise the door curtain to the desired height, rotate the upper limit screw sleeve to touch the micro switch, and tighten the screws when you hear a "click" sound; then lower the door curtain to the ground, determine the position of the lower limit screw sleeve in the same way, and finally tighten the two set screws with your fingers.

6. Instructions for use:

● The rolling door machine is a short-time working system, and the continuous operation time shall not exceed 7 minutes;

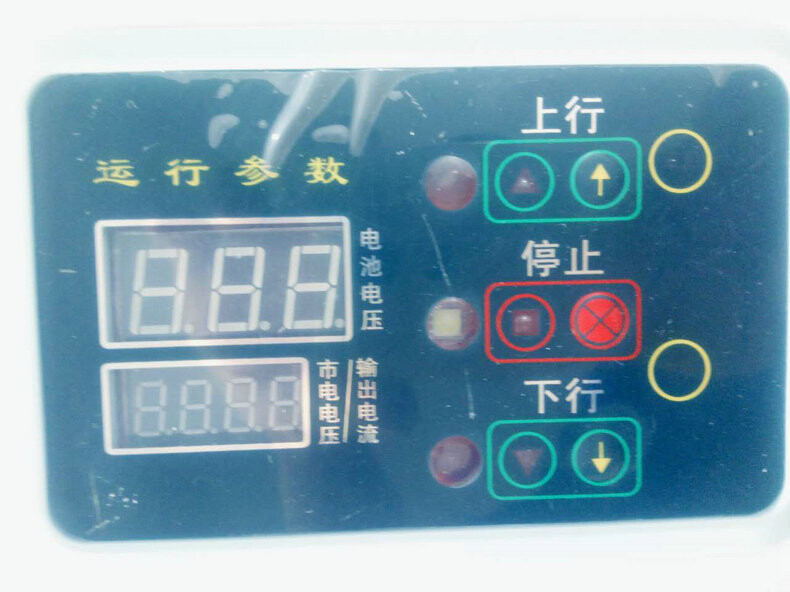

● The operation of the rolling door machine is controlled by the "up", "down" and "stop" on the remote control or button. When pressing the "up" or "down" button, if there is no rising or falling action, you must immediately press the "stop" button to cut off the power supply to avoid burning the motor;

● When the power is off, use the hand chain to raise the door curtain. It is strictly forbidden to exceed the set height to avoid damaging the limit switch and causing the top; to close the door curtain, you can gently pull the manual pull rod to make the door curtain drop at a uniform speed. When the door curtain is about to be fully closed, you should loosen the pull rod and then pull it again to fully close to prevent damage to the limit switch;

● When thunderstorms occur, disconnect the external power supply as much as possible;

● When using the rolling door machine, the operator must not leave the site. If any abnormal situation is found, the power supply should be cut off immediately. It can be used again after the fault is eliminated.

Related Suggestion

Rolling door machine power storage box power storage control box AC/DC controller with infrared beam stop when encountering obstruction

Rolling door machine power storage box power storage control box AC/DC controller with infrared beam stop when encountering obstruction Encountering obstacles, stopping storage, electric box, rolling door controller, high-quality rolling door controller, UPS, encountering obstacles, stopping storage, electric treasure

Encountering obstacles, stopping storage, electric box, rolling door controller, high-quality rolling door controller, UPS, encountering obstacles, stopping storage, electric treasure Red Diplomatic DC Power Storage Box Power Storage Treasure with Battery Power Storage Box AC/DC Power Storage Box Power Storage Controller

Red Diplomatic DC Power Storage Box Power Storage Treasure with Battery Power Storage Box AC/DC Power Storage Box Power Storage Controller Boutique power storage box Rolling door machine power storage box Rolling door controller sales Power storage box factory direct sales

Boutique power storage box Rolling door machine power storage box Rolling door controller sales Power storage box factory direct sales

Online Consultation